PredictablePROJECT DELIVERY

TRUST. AS STRONG AS OUR STEEL.

We are your trusted partner to provide solutions to challenges that are inherent to the traditional construction approach. Through influencing the project design, creating and utilizing intelligent models, we work alongside your team during the conceptual stage of your project to ensure predictability. Our process ensures optimized budget, schedule and most importantly, safety.

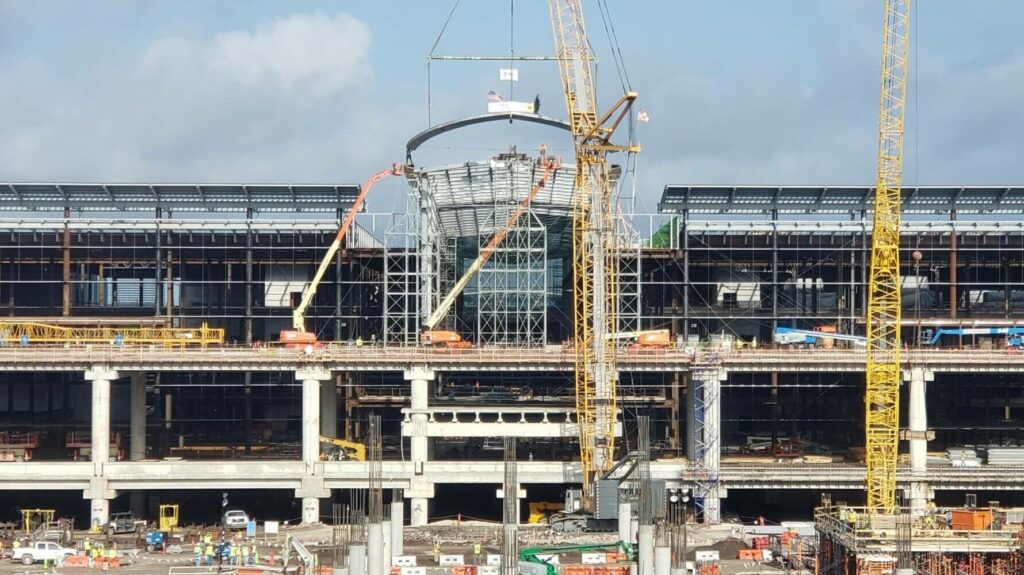

WE THRIVE IN

THE COMPLEX

Complex structural steel projects are our sweet spot. Our extensive project experience allows us to partner with our clients in the early schematic stages of a project to reduce risk and accelerate construction timelines on some of the most intricate, gravity-defying structures in logistically-challenged locations.

IT’S ALL IN THE DETAILS

We leave no stone unturned, no detail forgotten, taking into consideration everything in order to hedge against constructability issues that frequently arise. Our early design suggestions are regularly incorporated into the New York City Department of Building’s permit issuance process before contract awards are even made. With this voice of authority and decades of experience, we provide guidance on logistics such as:

- Crane mobilization

- Labor considerations

- Below grade utility and transit considerations

- Transportation studies and considerations

- Core protection platform and shoring placement

- Deconstruction of previous buildings

- Terrain considerations

- Overall schedule impacts

TECHNOLOGY THAT

DE-RISKS THE PROJECT

We utilize best in class technology including laser scan and model-based workflows to identify clashes and anticipate constructability issues before they occur. During this phase, we make design suggestions that improve the constructability of the project while considering budget, planning logistics, fabrication and erection. Our fabrication expertise combined with the use of innovative technology uniquely positions us to provide guidance on logistics that will ultimately impact your project’s bottom line.

MAXIMIZE SCHEDULE.

MINIMIZE FINANCIAL

IMPACTS.

Optimizing the project design without sacrificing the architect and EOR’s vision can be challenging. We understand the various facets of structural design and can offer practical solutions for both design and budget. With our experienced and professional in-house engineering staff, we evaluate various scenarios pulling from our deep expertise to help guide you to an informed decision that maximizes schedule and minimizes financial impacts.

DESIGN ASSIST

Our dedicated team of 15 inhouse Design Assist Engineers are pioneers of this methodology dating back to the early 2000’s and have optimized designs for over 400 projects.

With the implications of schedule, labor and material decisions so tightly entwined, this ensures foresight for you to make the best design decisions before they have an adverse effect. Working alongside your team, and backed by the industry experts in our procurement, fabrication and erection departments, our optimized solutions can minimize:

- The project timeline by up to 12 weeks.

- Cost of structural steel scope by up to 25%.

- Coordination of RFI’s and submittal revise and

resubmits by up to 33%. - Safety risk.

- Wasted material.

MODULARIZATION

Our fabrication, logistics planning and construction experience enables us to influence design for modularization to enhance constructability, reduce cost in the safest way possible and drive high labor costs out of the field. Our experience spans modularizing assemblies of all sizes. If your project is best suited for a modular approach, the greatest benefit is realized when we are involved early in the schematic phase.

Strategies that protect

MATERIAL PROCUREMENT

Our dedicated supply chain team helps you navigate the volatile steel markets.

MARKET SUPPLY & DEMAND

We monitor factors that impact mill and supplier ability to supply product to meet our clients

MILL SCHEDULING & PRICING

Our strong mill relationships and our volume leverage allows us to negotiate best pricing for our customers while prioritizing scheduling

ECONOMIC INDICATORS & MARKET RISKS

We constantly monitor and analyze economic indicators and global risks to mitigate interruption and volatility in our material orders